Inspection

The outcome of all the state of the art machinery and process is still confirmed from strong inspection and metallurgical systems. The inspection systems used are from the very best and highly accurate. These systems are in place to ensure our customers get their parts trouble free and also to meet our goal of <100PPM.

Our Inspection procedure aims:

To achieve high standards of performance by continuous improvements

To achieve total customer satisfaction

To maintain high standards of business policies ensuring a fair deal to all our customers thereby assuring honesty, transparency and adherence to business ethics in all our transactions.

Surface Coating Thickness Tester

Compact and Easy Roughness Measurement

The mobile HOMMEL-ETAMIC W5 roughness measuring instrument provides a high level of performance and operating convience for roughness measurement in production. The functional design makes it incredibly easy to use and allows the device to fit and securely in your hand when it comes to mobile measurement.

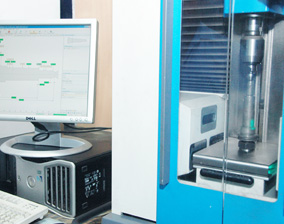

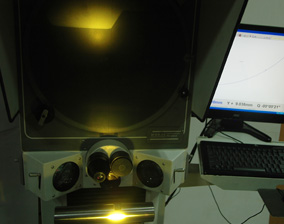

Optical Measuring System

Metrology for use in the production environment makes very high demands on the technology and production quality. Our shaft measuring systems more than satisfy these demands.

The Hardware and software are optimized for use in a production environment and are able to offer gauging component capability with maximum reliability over long periods of time.

Evalution Possibilities

1. Diameters & Lengths

2. Geometry Elements, Workpiece profile

3. From & Position Tolerances

4. Rotation Angle

5. External Thread

6. Through Hole Contour